Surface Treatment

Amorphous Alloy Coatings

We solve our customers’ problems with amorphous alloy spraying that uses next-generation metals.

What is an amorphous alloy (metallic glass)?

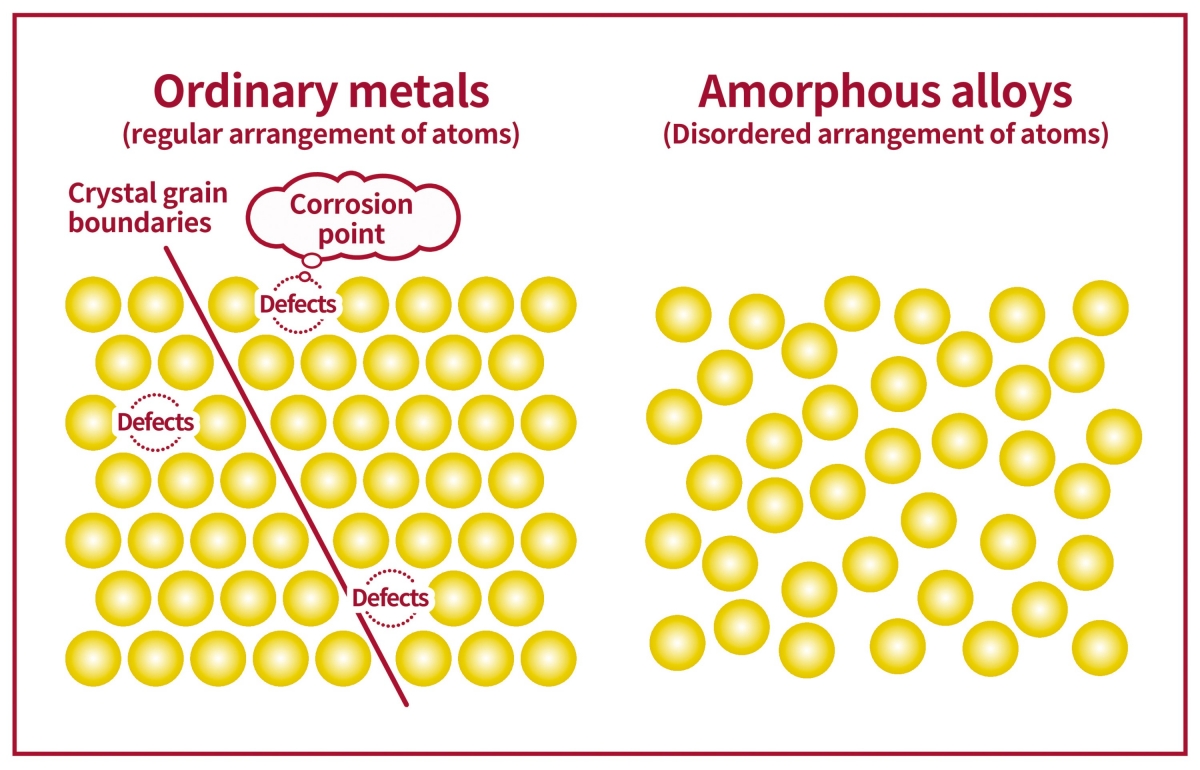

In normal metals atoms are arranged in a highly ordered manner, creating crystal grain boundaries and defects. When they are subjected to external forces, transfers due to crystal grain boundaries and defects occur, causing the shapes to change.

On the other hand, the atomic structure of amorphous alloys have a disordered arrangement, like a liquid. Therefore, they don’t have the characteristic sliding surfaces as crystalline metals have, and therefore they exhibit high levels of strength and toughness.

Basically, the higher something’s strength is, the lower its toughness becomes. But amorphous alloys, thanks to their disordered atomic arrangements, exhibit high levels of strength and toughness simultaneously, and as such are ideal high-strength materials (the highest will have a Vickers hardness of 1000 HV or more).

Moreover, heterogeneous features such as crystal grain boundaries and defects do not exist, so amorphous alloys show high corrosion resistance due to their forming passivation films uniformly (the corrosion resistance is more than tens of thousands of times that of stainless steel).

On the other hand, the atomic structure of amorphous alloys have a disordered arrangement, like a liquid. Therefore, they don’t have the characteristic sliding surfaces as crystalline metals have, and therefore they exhibit high levels of strength and toughness.

Basically, the higher something’s strength is, the lower its toughness becomes. But amorphous alloys, thanks to their disordered atomic arrangements, exhibit high levels of strength and toughness simultaneously, and as such are ideal high-strength materials (the highest will have a Vickers hardness of 1000 HV or more).

Moreover, heterogeneous features such as crystal grain boundaries and defects do not exist, so amorphous alloys show high corrosion resistance due to their forming passivation films uniformly (the corrosion resistance is more than tens of thousands of times that of stainless steel).

Amorphous alloy coating technology

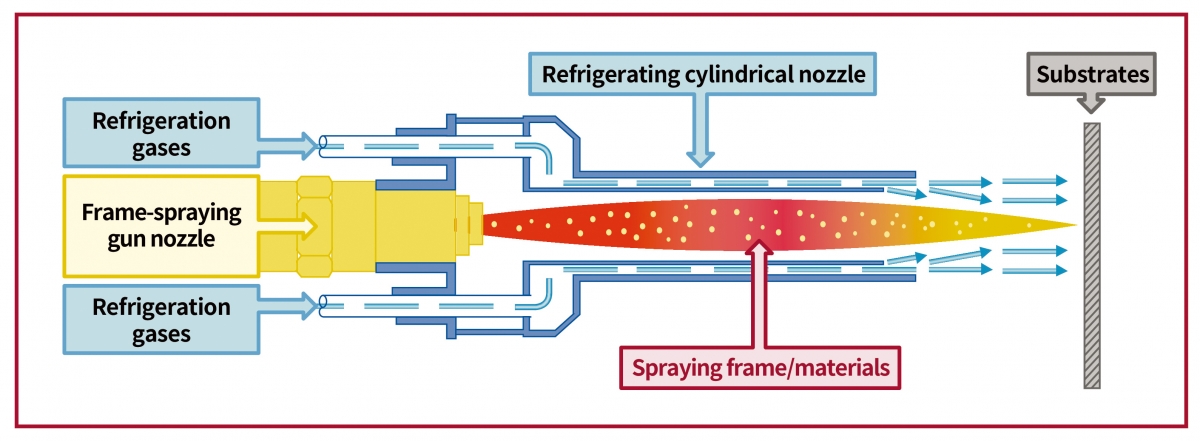

Generally, we need to cool molten metals very quickly to create amorphous alloys. Therefore, only limited amounts of amorphous alloys could be produced, and this was an obstacle to their becoming popular.

We are making efforts to conduct R&D on and manufacture highly functional coatings while carrying out a joint research project with Tohoku University, which is famous for its cutting-edge research on amorphous alloys.

We are making efforts to conduct R&D on and manufacture highly functional coatings while carrying out a joint research project with Tohoku University, which is famous for its cutting-edge research on amorphous alloys.

Special thermal spraying equipment

- Able to spray a large area

- This can be applied to various shapes

Developed thermal spray equipment

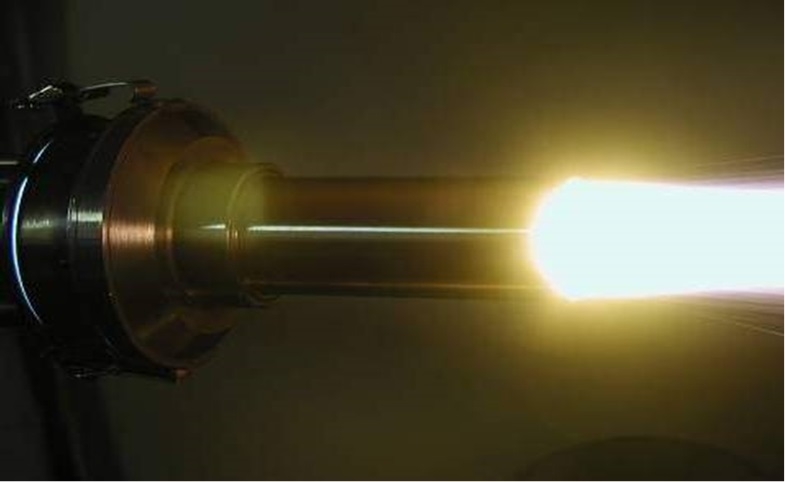

Photograph of thermal spraying

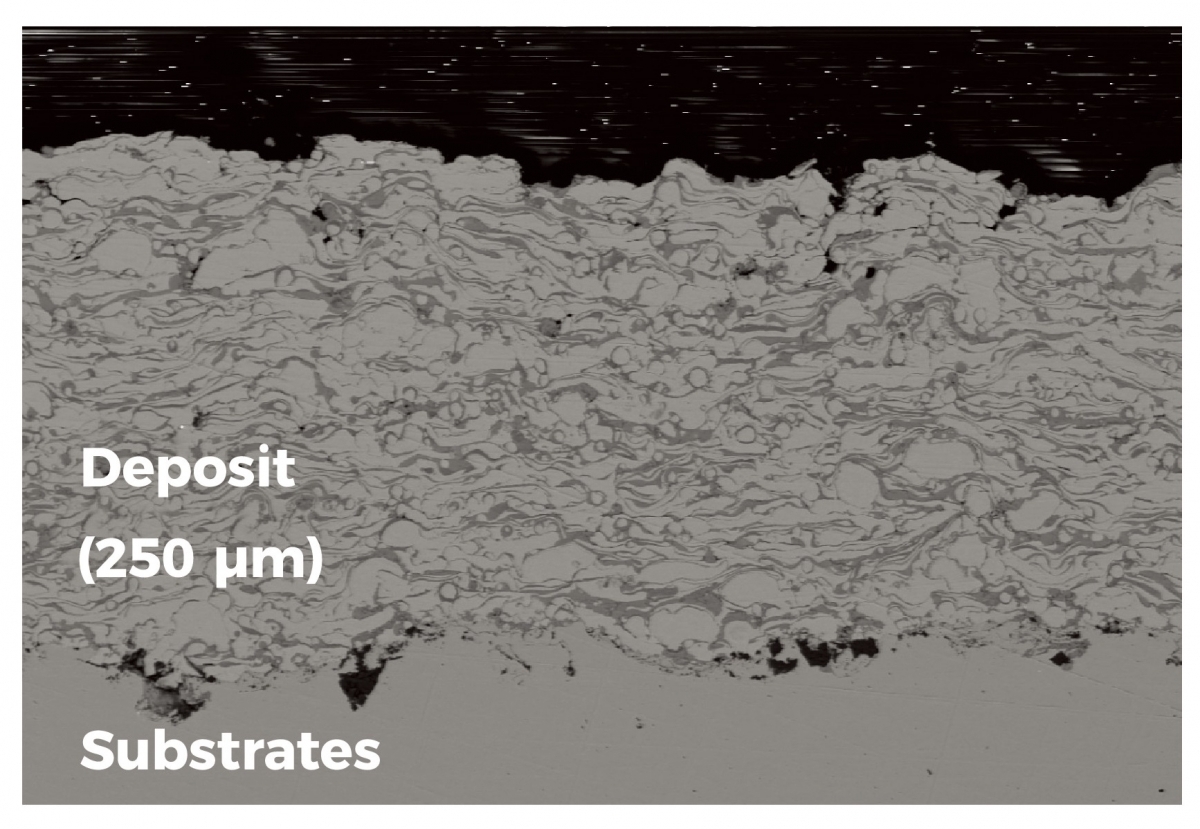

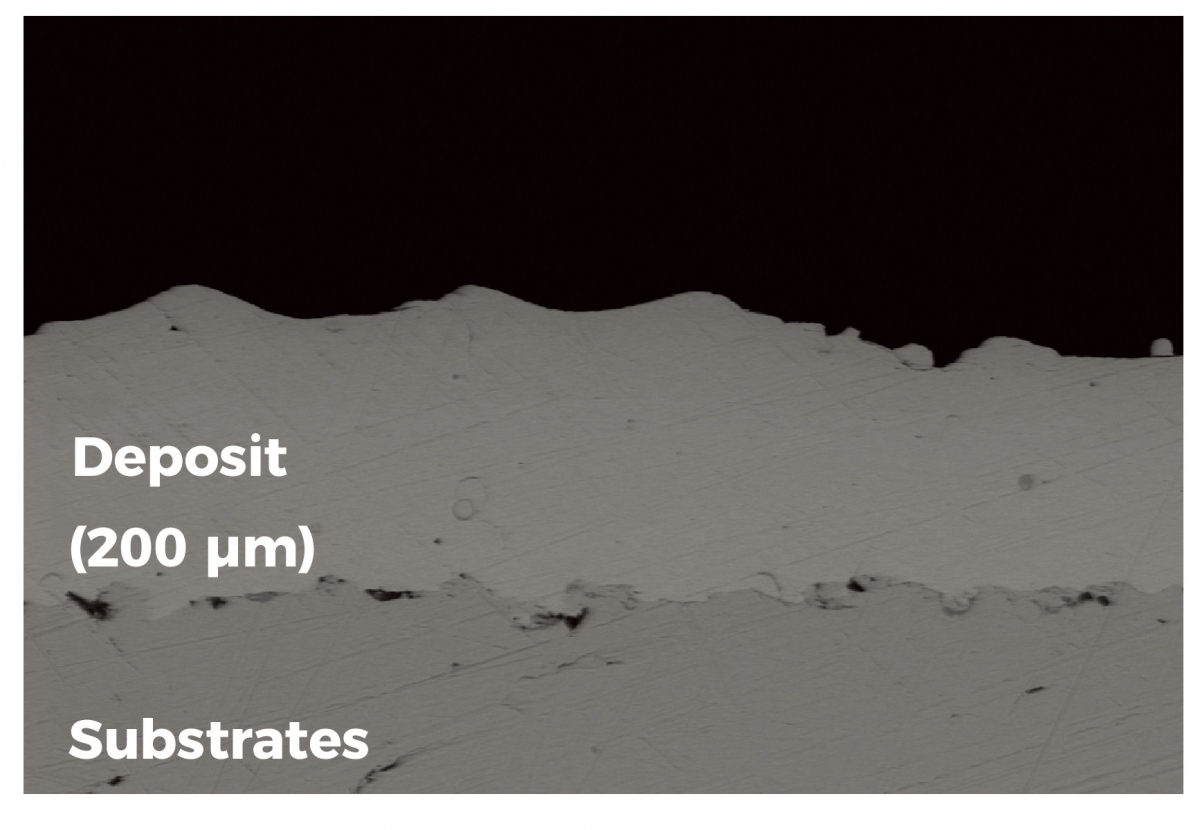

Cross-sectional view of spray deposit

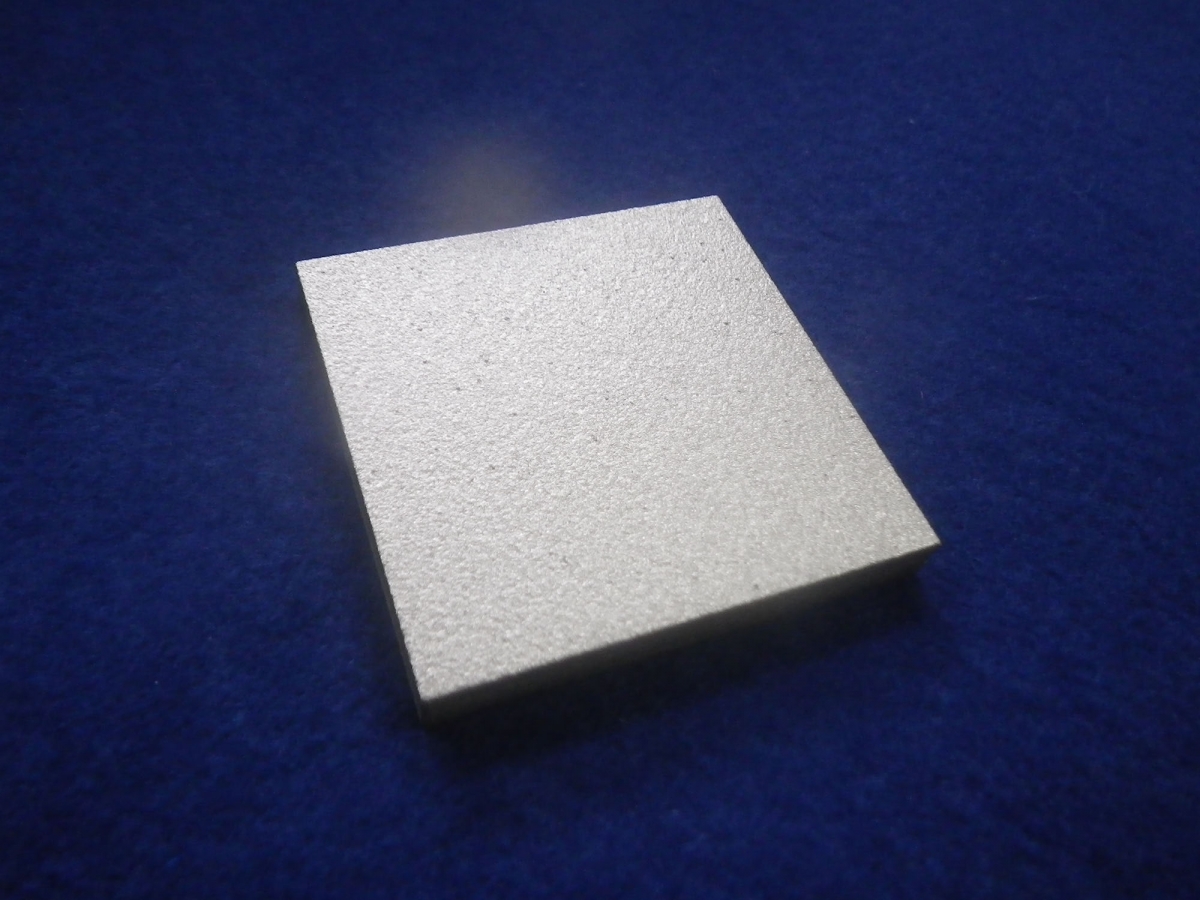

Appearance

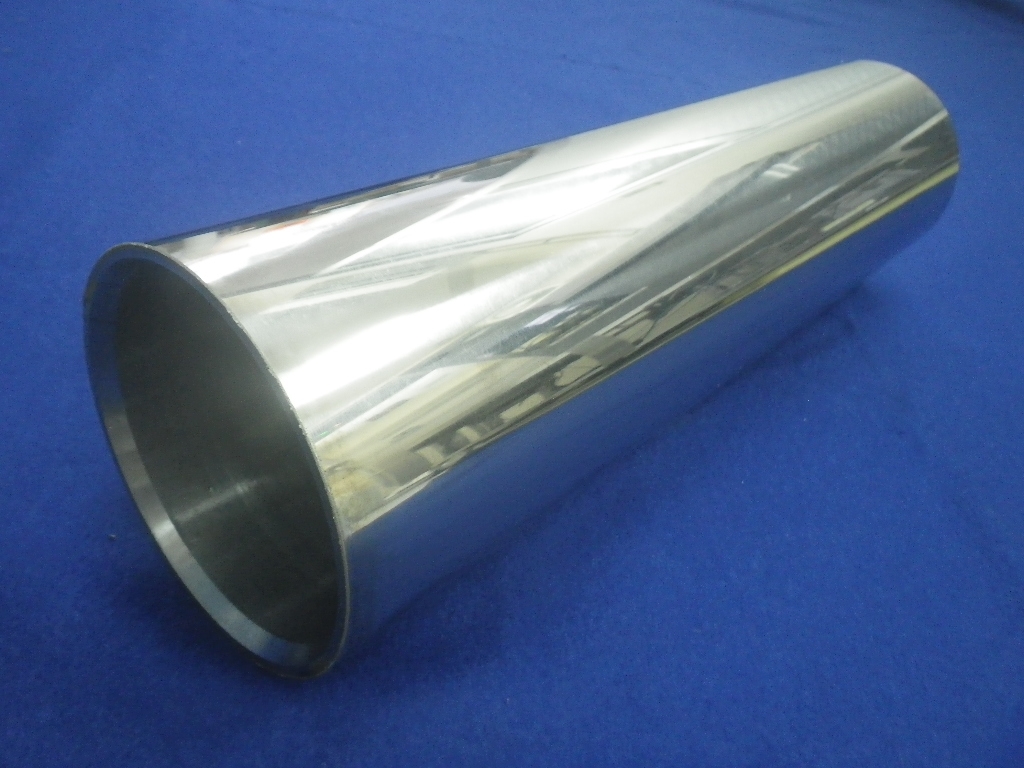

Application case studies

Stirring impeller used in pH 2 slurry