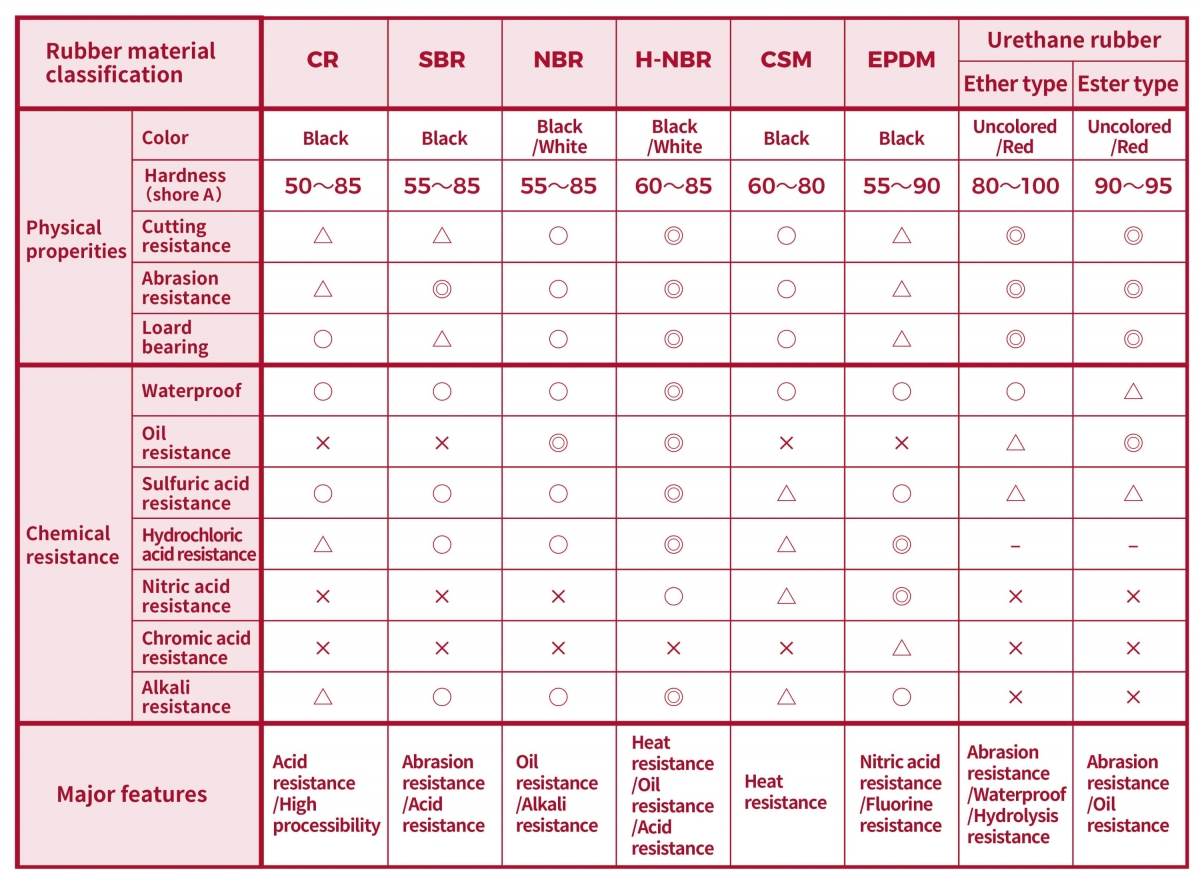

Surface Treatment

Rubber Lining

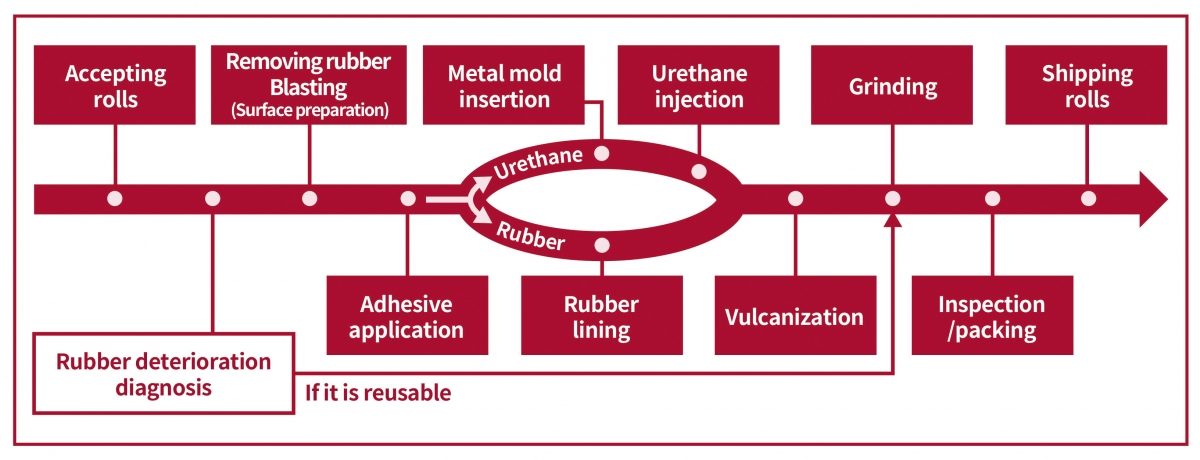

Manufacturing process

Lineup

Effectiveness of rubber lining

- Pressure resistance

- Thermal resistance

- Cutting resistance

- Abrasion resistance

- Oil resistance

- Acid resistance

- Alkali resistance, etc.

Pressure resistance and abrasion resistance

Large diameter urethane rollers

We can produce oversized urethane rollers as large as φ1200 mm. We can cut diamond shapes or other shapes according to your needs on the surface.

- Outline dimensions: φ1000*1600 mm long

Sponge rubber tire

Sponge rubber tire for steel carriages. We polish its surface after coating the metal core with urethane.

- Outline dimensions: φ400*300*200 mm

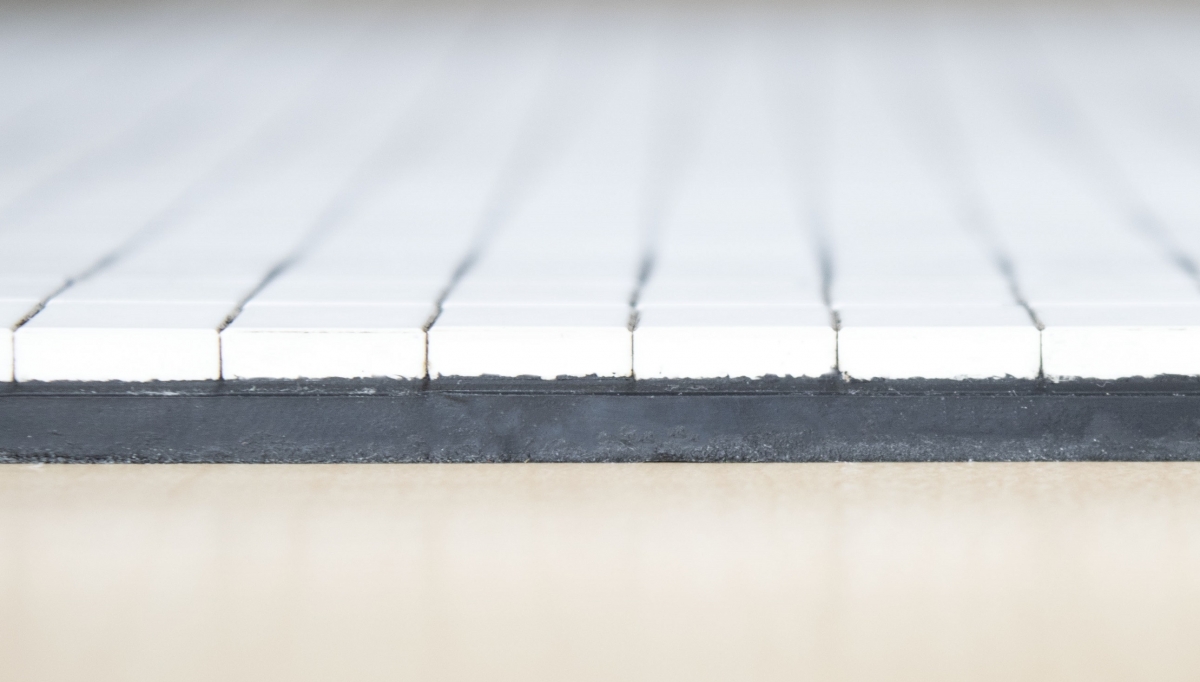

Pulleys

Ceramic chip pulleysRolls covered with fine ceramic chips (10 mm square). Ceramics give it high abrasion resistance.

- Outline dimensions: φ400*1350 mm long

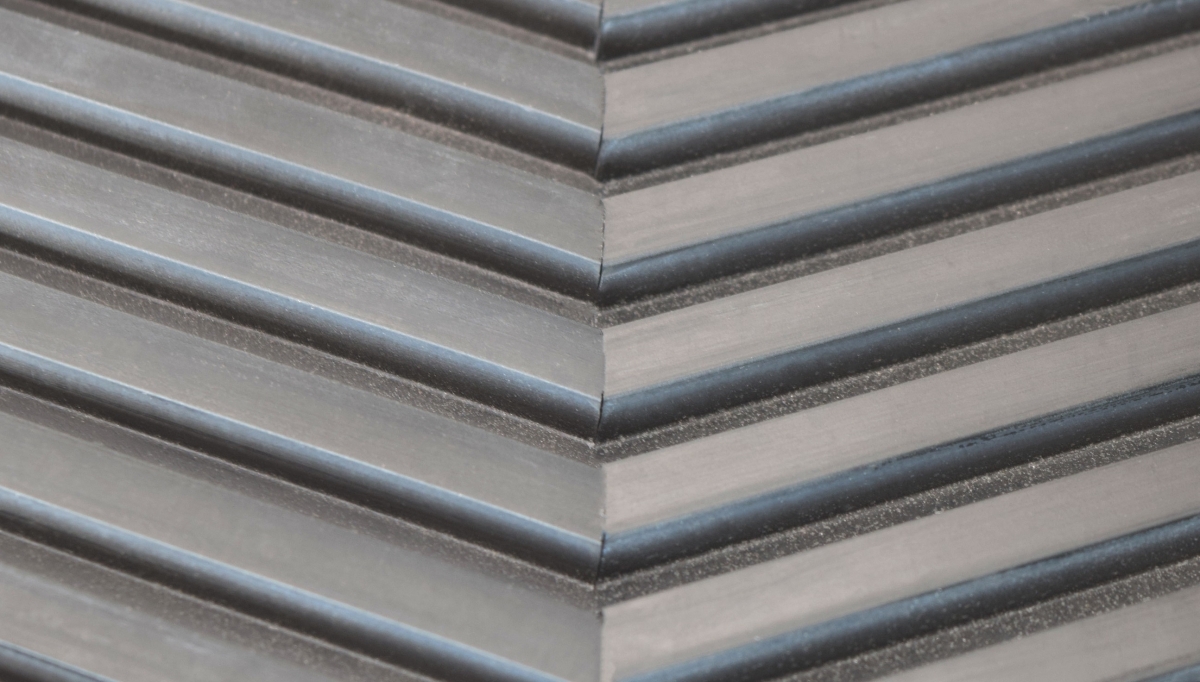

Grooved pulleys

Grooved rubber rolls. Grooving gives it high grip performance.

- Outline dimensions: φ660*1450 mm long

Acid resistance/Oil resistance

Rolls for steel production

Rolls that come in direct contact with chemical solutions in descaling process for steel sheet manufacturing. We provide proper type of rubbers in accordance to the chemical solutions used.

- Outline dimensions: φ200*1100 mm long

- Outline dimensions: φ450*1500 mm long

Coupling parts

Cover sheet to hold grease to protect driving units for machines. Oil-resistant rubber is used for the parts that come in contact with oil.

Other features

Visibility

- Outline dimensions: φ200*1200 mm long

Lightweight rubber lined rolls

Lightweight rolls made of CFRP (Carbon Fiber Reinforced Plastics). These rolls can be carried by hand, reducing labor.