Steel

Scrap

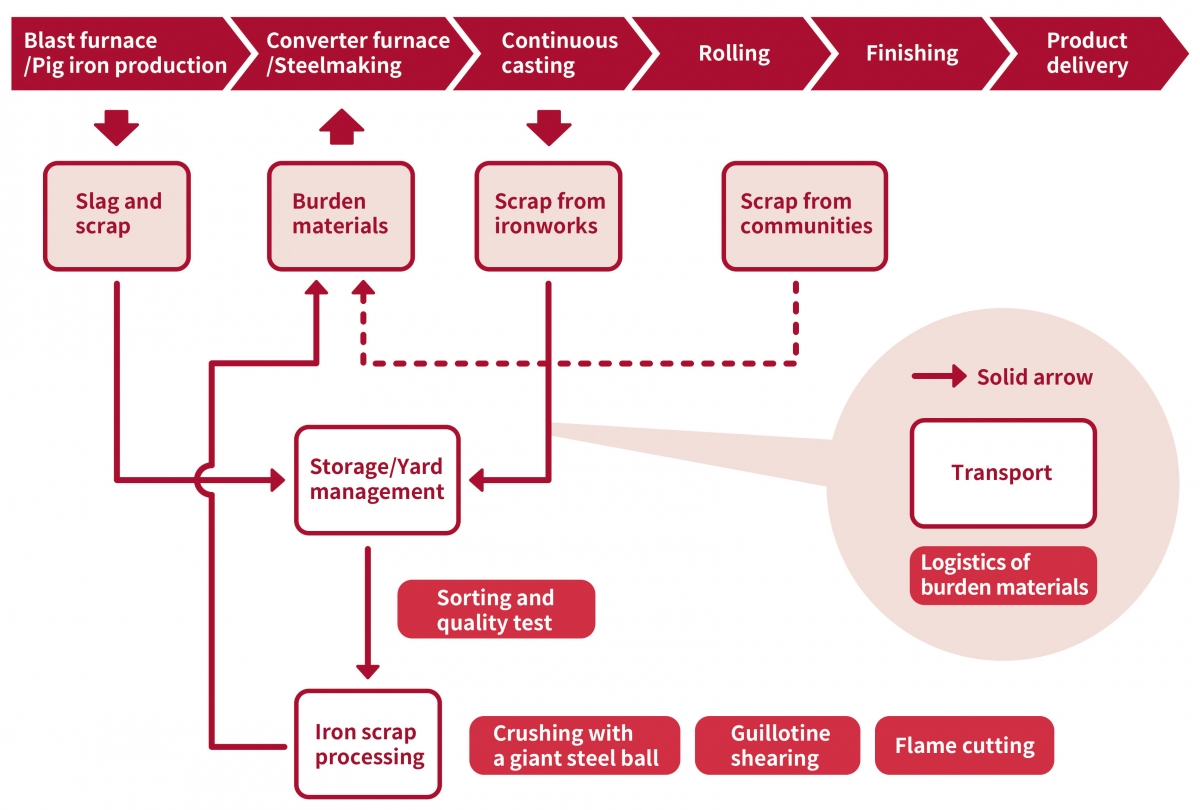

Yoshikawa Kogyo recycles scrap from ironworks and communities into burden materials for converter furnaces. Ever greater productivity is pursued with leading-edge shearing machines, and large-scale machinery for handling and transporting scrap.

Collected scrap is carefully inspected and sorted to supply materials of the expected quality to clients in a timely manner for their steady production operations.

For instance, we have proposed and successfully built our own logistics system to ensure timely supply of the right amount of recycled materials to the ferroalloy melting furnace operated for steel production by Kyushu Works at the Yawata Area.

Logistics of burden materials

Scrap from processing lines at ironworks and disused ironware are collected at our scrap yards for delivery as burden materials for converter furnaces at steel plants.

The logistics operation is planned and conducted to ensure reliable and timely delivery to ensure steady steel production by clients.

Many kinds of specialized vehicles and heavy machinery have been deployed to handle various materials and tasks.

Sorting and quality control

Processing

Crushing with a giant steel ball

Guillotine shearing

Flame cutting

Bulky pieces of scrap that cannot be handled by guillotine shears are cut with gas burners according to their conditions and sizes. The task requires accomplished skill and experience.

Most of the bulky large pieces of iron scrap we buy are disused machines. We handle their collection, flame cutting, and delivery to clients.