Steel

Processing

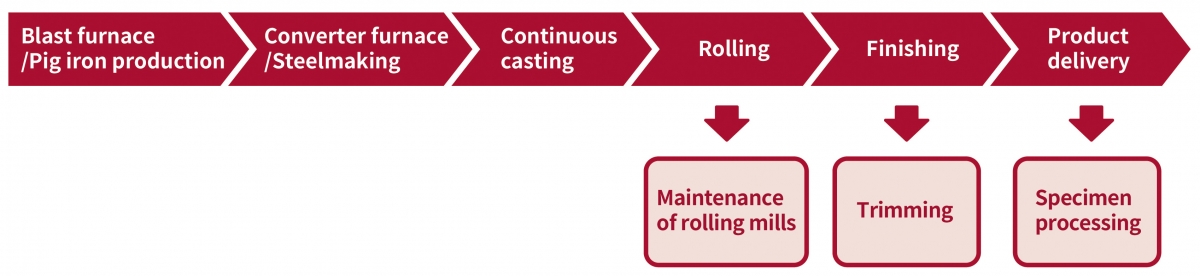

Yoshikawa Kogyo handles various processes on behalf of ironworks. We are even able to maintain and repair equipment for rolling, trimming, and cold processing.

Our clients highly evaluate our original proposals for managing specimen processing by means of laser marking.

Trimming

We perform cutting, surface grinding, painting, and so on to deliver processed sheet steel of the specified quality.Our portable cutters and flame planers perform both cold and hot cutting of intermediate or even extremely thick steel plates with a high dimensional precision.

Maintenance of rolling mills

We polish, repair, and fill the surface of rolls that are vital for hot rolling, cold rolling, and processing tin sheets or other thin metal sheets. These advanced technologies underpin steelmaking.

Our know-how in repairing and remodeling roll grinders helps clients reliably achieve their production plans.

Specimen processing

Our specimen processing center produces specimens for material testing and quality assurance of steel products from each ironworks plant.We also produce specimens for material development at research institutes and the like.Each specimen is laser marked with an ID code to avoid commingling of unwanted materials. The management of these optically scannable codes is computerized.Conditions associated with such ID codes can be applied for numerically controlled processing and process management. Even more original system technologies are employed to rigorously manage quality and delivery deadlines.

Tasks performed

Process

Maintenance of rolling mills

Roll grinding, disassembly, assembly, inspection, and maintenance of chocks and bearings, repair and remodeling of roll grinders, roll surface treatment. (e.g., electrical discharge texturing, shot blast texturing, and plating)

Refinement of products

Thick plates

Flame cutting of sheet steel, defect inspection and conditioning of sheet steel, press straightening, trimming of a large thick steel plate.

Hot extrusion

Conditioning of semi-finished goods, conditioning of products, binding.

Thick cylinders

Flaw detection, scraping.

Cold processing

Production of adjustment chips for molten steel temperature.

Specimen processing

Sampling for product testing and sample processing.